Precision CNC Machine Shop Westbury

CNC Machine Shop

5 Axis CNC Milling Machine

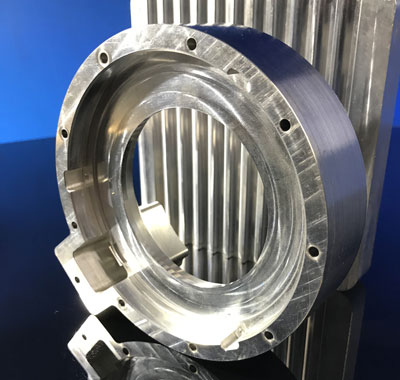

We utilise 5 axis CNC positional milling which enables us to machine 5 sides of a component in 1 single set up. This gives us a competitive edge when tackling components with tight feature relationships, that would otherwise be difficult if the part needed to be moved to another machine or re orientated by the operator.

CNC Turning

The machines also utilise touch probes for quick and accurate setting of work coordinate offsets and they also use on board tool length pre setters.

We have the capability of CNC turning with 4 axis and live tooling. This means we can machine cylindrical components up to 250mm diameter and mill features in the X or Z direction without removing them from the CNC machine. This is again, another way for us to retain dimensional relationships between features and also reduce cycle / processing times.

CNC Cutting Service

Hydraulic Automatic Saw

Our hydraulic auto saw is another force multiplier, as we can set this up for repetitive cutting of billets in house which reduces the cost and lead time of buying in precut material and enables us to run and set machines while the material is being cut.

CNC Laser Cutter

We can also use laser cutting as an alternative metal cutting service. This uses a laser beam to vaporize and remove excess material making it extremely precise and accurate.

Swiss Turning

We have implemented swiss style sliding head lathe technology. These machines are built to perform at the highest level of accuracy within the production of small diameter components in high volumes.

The machines are fed with a full length bar feed which can be loaded with enough material to run unattended for hours, with a maximum bar capacity of 16mm diameter. This enables us to run very large quantities of simple to complex components at a very competitive rate, compared to the attended running of the larger machines.

Contact Us

Require some local CNC expertise? Please get in touch about your project. We offer specialist services to local customers in the Westbury/Wiltshire area as well as those further afar.

Find out more about our work by reading through our case studies.